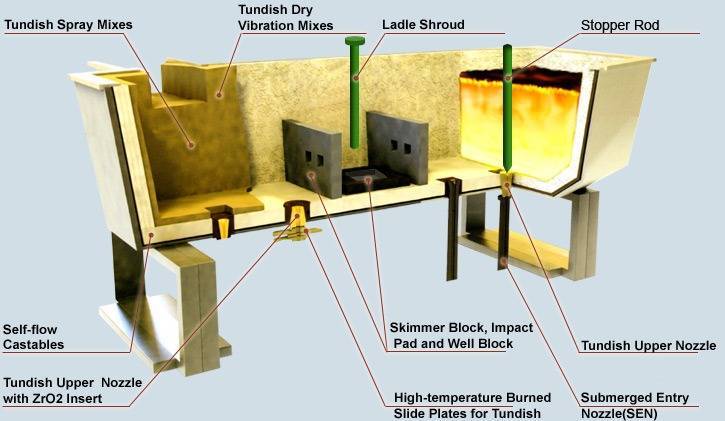

Refractory products for Tundish application

Mono Block Stopper (Stopper rod)

Honsin Group develops multiples kinds of stoppers by selecting different raw materials properties :

aluminum carbon based,

aluminum-zirconium carbon based

aluminum-magnesia carbon based.

Our products perform well in very strict conditions ...

Ladle Shroud

Honsin Group supplies different categories Ladle Shroud such as :

reheating type

non-preheating type

argon blowing type and not argon blowing type

Different kinds of materials have been rigorously selected, tested to offer our customers ...

Submerged Entry Nozzle

Honsin Group supplies different categories submerged entry nozzles such as :

plug-in type

hanging type

fast changing type

Different kinds of materials have been rigorously selected, tested to offer our customers the most adapted solution ...

Zirconia Metering Nozzle

The Zirconia metering nozzle is specially used for the Tundish gating system without plug stick in the small square-base continuous casting machine. It is perfectly adapted with multi-thread and small square-base continuous casting machine.

All our...

Tundish Slag Dam and Impact Plate

Tundish Slag Dam

The Tundish slag dam is an auxiliary product in the Tundish. It is used to separate slag, prevent slag going into moulds and improve steel quality. This product is characterized by good erosion resistance, high-temperature stability. Our e...

Tundish Well Block

Selected from high-quality raw materials with rigorous production process. Honsin Group Tundish well block can be used with multiples kinds of Tundish nozzles.

Our Tundish well block shows excellent strength, high thermal shock stability and erosion...

Tundish Castable

Honsin Group Tundish castable is formed with extra alumina as the principal raw material. It is characterized by the stability of heat and shock resistance, high strength without chipping.

Typical product characteristics tables :

Item

...

Dry Vibration Mix

This product is mainly used for Tundish lining. It is characterized by easy usage. It allows to prevent molten steel from refractory pollution efficiently. Without adding water during the installation, construction time is dramatically reduced.

Typical...

Tundish Spray Mixes

Spray mixes become priority selection of Tundish working linings for lots of steel plants. By using spray mixes, continuous casting time can be extended to 25 hours or more.

Typical product characteristics tables :

Item

HSTM-1

...